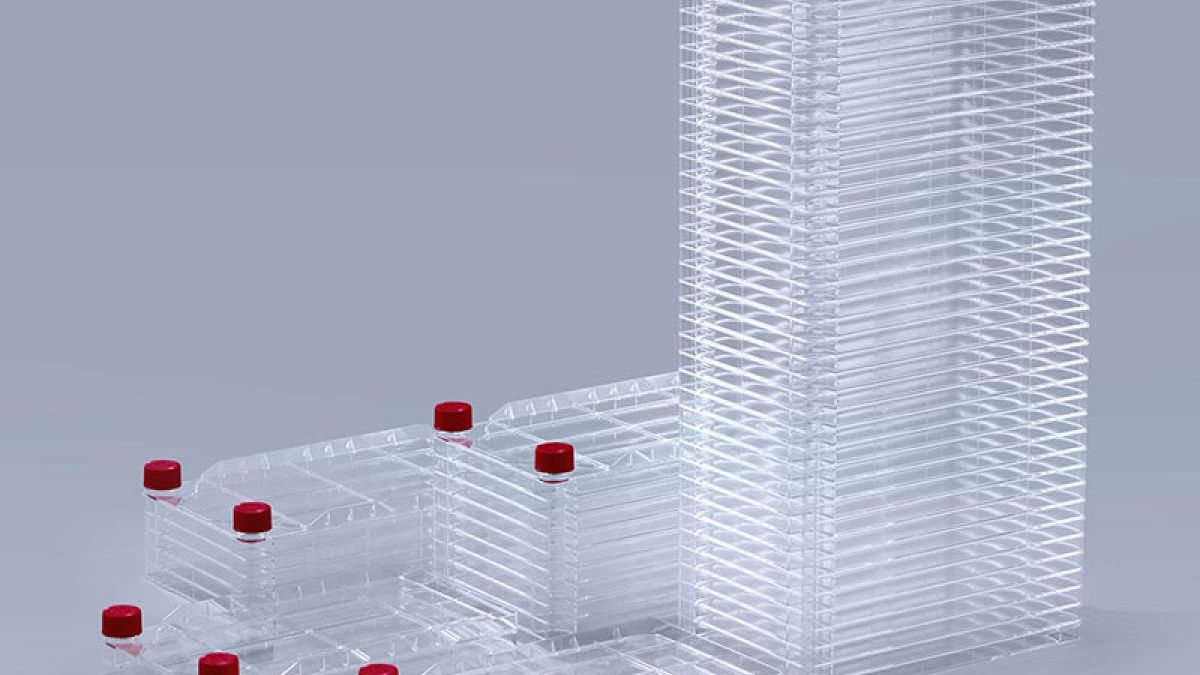

For adherent stem cell types, the cell factory, particularly the Multilayer Cell Factory, has become a widely adopted solution for expanding cell numbers while maintaining controlled culture conditions. However, alongside its advantages, the use of multilayer systems also presents specific technical and process-related challenges that must be carefully addressed.

Stem cell technology plays a critical role in regenerative medicine, cell therapy, tissue engineering, and drug discovery. As stem cell research advances toward clinical translation and commercial manufacturing, the demand for scalable, standardized, and reproducible culture platforms continues to grow.

For adherent stem cell types, the cell factory, particularly the Multilayer Cell Factory, has become a widely adopted solution for expanding cell numbers while maintaining controlled culture conditions. However, alongside its advantages, the use of multilayer systems also presents specific technical and process-related challenges that must be carefully addressed.

1. Role of Multilayer Cell Factory Systems in Stem Cell Cultivation

Most stem cell types—including mesenchymal stem cells (MSCs), induced pluripotent stem cells (iPSCs), and certain embryonic stem cells (ESCs)—exhibit adherent growth behavior. These cells require consistent surface properties, precise environmental control, and gentle handling to preserve their viability and functional characteristics.

Multilayer Cell Factory provide:

Large, uniform adherent growth surfaces

TC-treated culture layers supporting stable cell attachment

Compact design for high surface-to-volume efficiency

By stacking multiple culture layers into a single unit, a cell factory enables high-density stem cell expansion without increasing incubator or cleanroom space requirements.

2. Key Applications in Stem Cell Manufacturing

2.1 Expansion of Mesenchymal Stem Cells (MSCs)

MSCs are widely used in clinical research and cell therapy applications due to their immunomodulatory and regenerative properties. Multilayer Cell Factory systems are commonly applied in:

Large-scale MSC expansion

Autologous and allogeneic cell therapy production

Preclinical and clinical trial material preparation

The ability to maintain consistent growth conditions across multiple layers helps ensure uniform cell morphology and growth kinetics.

2.2 Stem Cells for Regenerative Medicine and Tissue Engineering

In regenerative medicine, stem cells often serve as seed cells for tissue constructs. Cell factory platforms support:

High cell yields required for tissue engineering

Standardized cell expansion prior to scaffold seeding

Controlled, repeatable upstream processes

This makes multilayer systems suitable for early-stage manufacturing workflows in regenerative medicine.

2.3 Cell Banking and Process Development

During cell line development and banking, Multilayer Cell Factory systems provide a scalable environment for:

Master and working cell bank expansion

Process optimization studies

Media and surface treatment evaluation

Their modular format allows easy transition from small-scale studies to larger production runs.

3. Advantages of Multilayer Cell Factory for Stem Cell Culture

The widespread adoption of cell factory systems in stem cell cultivation is driven by several key benefits:

Scalability: Easy scale-up by increasing layer numbers without changing culture principles

Standardization: Consistent geometry and surface treatment improve reproducibility

Operational efficiency: Fewer handling steps compared to multiple single-layer vessels

Space optimization: High surface area within a compact footprint

These advantages make Multilayer Cell Factory systems particularly attractive for facilities moving toward GMP-compliant stem cell manufacturing.

4. Challenges in Stem Cell Cultivation Using Multilayer Systems

Despite their benefits, using multilayer cell factory systems for stem cell cultivation presents several challenges:

4.1 Maintaining Stem Cell Quality and Phenotype

Stem cells are highly sensitive to culture conditions. Variations in nutrient gradients, oxygen distribution, or surface interactions across layers may affect:

Cell phenotype

Differentiation potential

Senescence rate

Careful process optimization and monitoring are required to ensure consistent cell quality.

4.2 Media Exchange and Harvest Complexity

As the number of layers increases, efficient media exchange and cell harvesting become more complex. Improper handling may lead to:

Uneven nutrient distribution

Increased shear stress

Incomplete cell recovery

Closed-system tubing and pump-assisted workflows are often necessary to address these challenges.

4.3 Process Monitoring and Control

Unlike bioreactors, traditional cell factory systems have limited real-time monitoring capabilities. Parameters such as pH, dissolved oxygen, and metabolite levels are not continuously measured, requiring:

Well-defined operating procedures

Indirect monitoring strategies

Batch-end quality assessment

5. Integration with Closed and Automated Systems

To overcome these limitations, modern Multilayer Cell Factory systems are increasingly integrated with:

Closed single-use tubing assemblies

Peristaltic pump-driven media handling

Automated filling and harvesting systems

These integrations help reduce contamination risk, improve process consistency, and enhance suitability for clinical-grade stem cell production.

6. Future Perspectives

As stem cell therapies advance toward commercialization, the role of cell factory systems will continue to evolve. Hybrid solutions combining multilayer culture platforms with automation, digital monitoring, and advanced surface technologies are expected to improve both scalability and control.

Multilayer Cell Factory systems will remain a practical and flexible option for stem cell expansion, particularly in early-to-mid-stage manufacturing and applications requiring adherent culture formats.

Conclusion

Multilayer Cell Factory play an important role in stem cell cultivation by enabling scalable, standardized expansion of adherent stem cells. While challenges remain in maintaining cell quality, process control, and harvesting efficiency, continued technological improvements and process optimization are expanding their applicability.

With proper design and operation, the cell factory remains a valuable upstream platform supporting the growing field of stem cell research and therapy development.