The rapid advancement of gene and cell therapy has opened new frontiers in the treatment of cancers, genetic disorders, and rare diseases.

As research moves toward commercial-scale manufacturing, achieving stable, scalable, and contamination-free cell culture becomes a major challenge.

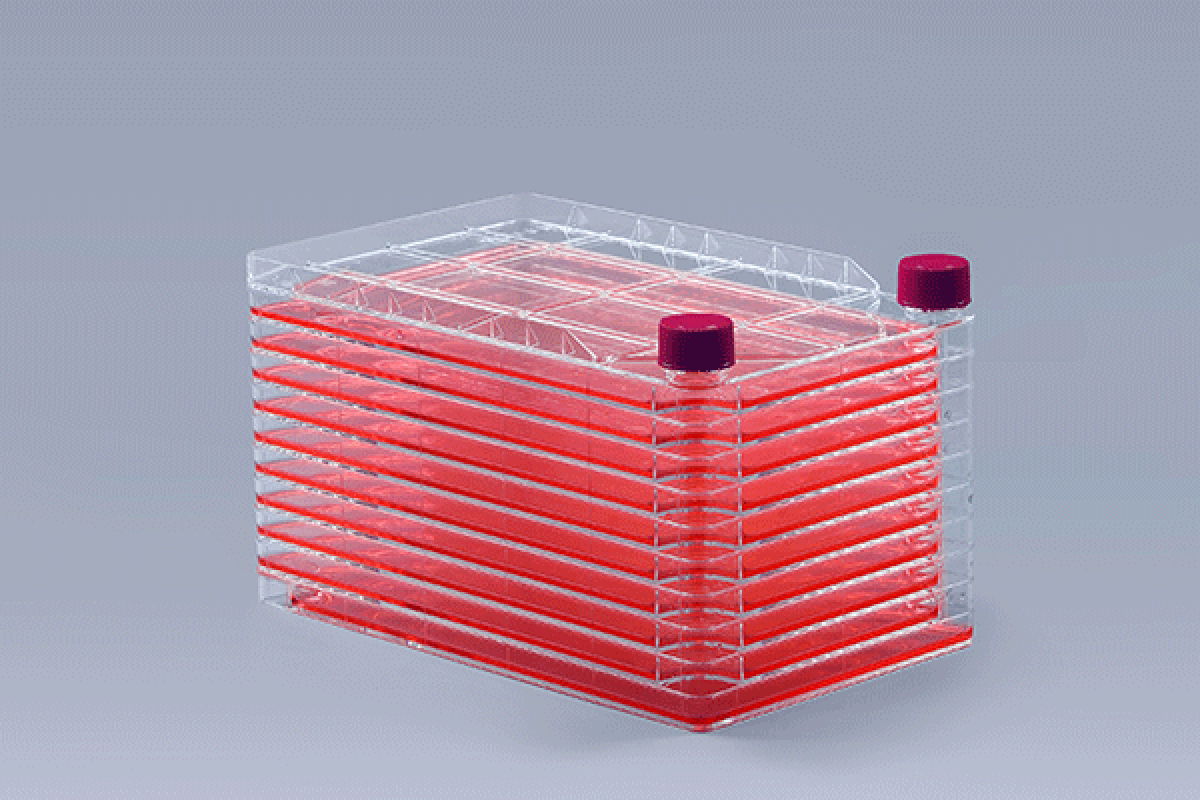

The cell factory—a high-performance, multilayer culture platform—is now widely adopted in viral vector production and therapeutic cell expansion, playing a vital role in the industrialization of advanced therapies.

1. Cell Factory: A Scalable Platform for Viral Vector Production

Viral vectors such as adenovirus (AdV), lentivirus (LV), and AAV are essential for gene therapy manufacturing. These vectors are often produced in adherent cell lines like HEK293 and Vero cells, which require stable growth environments and large surface areas.

Traditional roller bottles and single-layer flasks are limited in scale and consistency. In contrast, the cell factory provides:

High-density culture capacity within a compact footprint

Uniform gas exchange and nutrient flow across layers

Compatibility with closed, automated workflows

By enabling consistent viral vector yields with minimized contamination risks, the cell factory has become a cornerstone for*GMP-compliant biomanufacturing.

2. Supporting Cell Expansion for Cell Therapy

In cell therapy processes—such as CAR-T, stem cell, and regenerative medicine applications—the challenge is to expand cells efficiently while maintaining their functional properties.

The cell factory system, designed for large-scale adherent culture, offers an ideal solution.

Its TC-treated surface ensures optimal cell adhesion and proliferation, while integration with closed tubing assemblies allows for sterile media transfer and harvesting.

This setup provides a controlled environment for expanding therapeutic cells, ensuring product consistency and regulatory compliance throughout the process.

3. Multilayer Design for Efficient Scale-Up

The multilayer cell factory design is particularly suitable for laboratories and production facilities transitioning from research to pilot or commercial scale.

Each layer provides an equal and stable surface area, enabling predictable cell growth and efficient gas exchange.

By scaling from 1-layer to 40-layer configurations, manufacturers can easily adjust culture volumes without altering process parameters—offering flexibility and reproducibility in bioprocess development.

4. Integration with Automated and Closed Manufacturing Systems

Modern biopharmaceutical manufacturing increasingly relies on closed and automated operations to ensure process reliability.

The cell factory can be seamlessly integrated into:

Automated filling and harvest systems

Closed-loop tubing connections

Environmental monitoring systems for temperature, CO₂, and pH

Such integration minimizes manual handling, improves traceability, and maintains aseptic conditions—critical for the production of viral vectors and therapeutic cells under GMP standards.

5. Material and Design Reliability

FDCELL cell factories are manufactured from medical-grade polystyrene (PS) and undergo gamma sterilization for sterility assurance.

Features include:

TC-treated surfaces for uniform cell attachment

Leak-proof multilayer design ensuring safe handling

Compatibility with upstream and downstream connections

These engineering advantages make the cell factory a trusted choice for both research and industrial production environments.

Conclusion

As gene and cell therapy manufacturing expands globally, the cell factory stands out as a scalable, reliable, and cost-effective solution for adherent cell culture.

From viral vector production to therapeutic cell expansion, it bridges the gap between laboratory innovation and industrial bioprocessing.

With its multilayer design, closed operation, and GMP compliance, the cell factory system will continue to play a crucial role in shaping the future of advanced therapy manufacturing.