The transition from plate to flask is a crucial step in CHO early development. While microplates enable high-throughput selection, cell culture flasks provide the controlled, biologically relevant environment necessary to confirm clone robustness, metabolic stability, and scalability.

Early-stage CHO process development typically begins in microplates—96-well or 24-well formats used for clone isolation, viability assessment, and preliminary productivity ranking. However, data obtained from plates often cannot fully predict cellular behavior at larger scales. The transition from microplate cultures to cell culture flasks represents a critical step for verifying clone stability, metabolic patterns, and overall scalability.

A well-designed plate-to-flask workflow ensures that the selected clones are not only high-producing but also robust enough for subsequent shake flask and bioreactor development.

1.Why the Plate Stage Is Not Enough

Microplates are valuable for screening large clone libraries, but they present limitations:

Restricted gas exchange can distort pH and metabolic profiles

Small volume exaggerates nutrient depletion or waste accumulation

Adherence and morphology can be harder to evaluate

Automated systems may generate false positives in early productivity readings

Therefore, results obtained in microplates serve as a first filter, but deeper validation must occur in a controlled, scalable environment—namely, the cell culture flask.

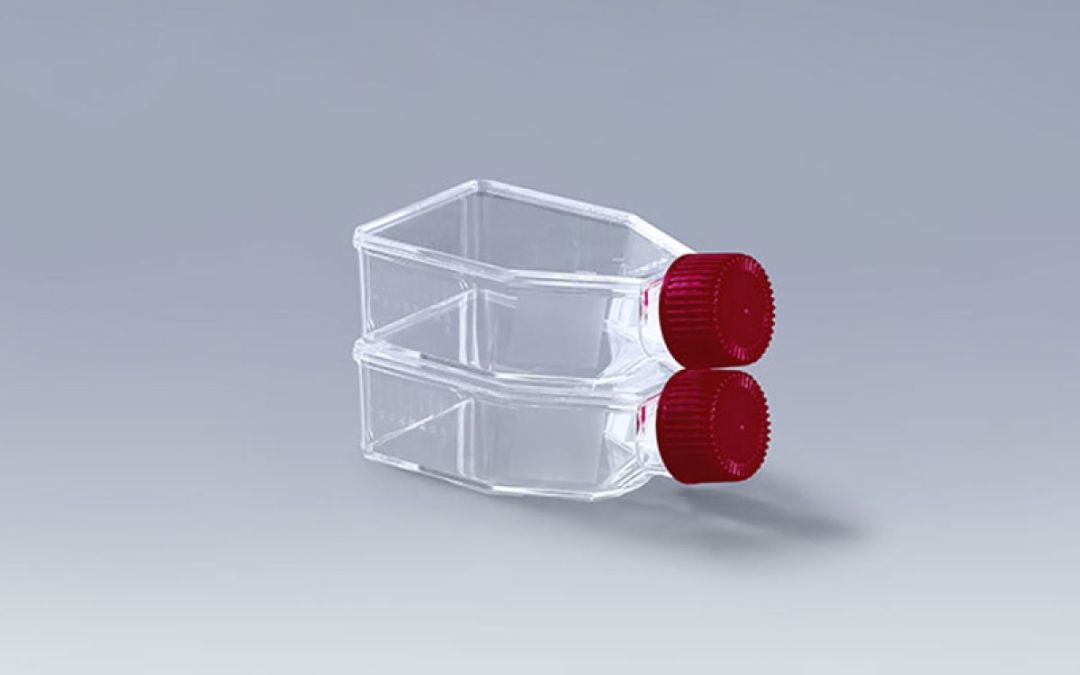

2.The Role of Cell Culture Flasks in Early CHO Expansion

Cell culture flask—typically made of TC-treated PS—provide a consistent surface and microenvironment for CHO growth. They are crucial for:

(1) Clone Expansion and Recovery

Gradual volume increase from plates to flasks prevents growth shock

Stable gas exchange supports consistent exponential growth

Clear observation window allows morphology and aggregation monitoring

(2) Assessing Genetic and Phenotypic Stability

Productivity trends across passages are more reliable in flasks

Early drift or loss of expression becomes visible

CHO morphology (vacuolation, granularity) is easier to evaluate

(3) Establishing Growth Kinetics

Doubling time, lag phase, and growth curve parameters

Seeding density optimization

Early evaluation of viable cell density ceilings

These metrics are vital for downstream scale-up design.

3.Media and Feeding Strategy Verification

Media that performs well in microplates may behave differently in flasks due to differences in oxygen availability, CO₂ regulation, and nutrient gradients. Cell culture flasks allow developers to:

Compare basal media formulations

Test feed strategies and nutrient supplementation

Verify metabolic stability (lactate, ammonia accumulation)

Screen additives at realistic culture volumes

By running multiple flasks in parallel, researchers can perform *mini-DoE* studies efficiently and cost-effectively.

4.Predicting Bioreactor Behavior Through Flask-Level Validation

Although cell culture flasks are not identical to bioreactor environments, the data obtained at this stage strongly correlates with later performance.

Growth kinetics:Defines seeding densities for shake flasks and reactors

Nutrient consumption:Guides feed composition and schedule

Stability across passages:Predicts long-term productivity Early product quality : Helps identify clones likely to maintain consistent glycosylation

By validating these parameters in flasks, process developers reduce risk during scale-up and minimize costly failures at larger volumes.

5.Advantages of Using Cell Culture Flask in CHO Workflows

Reproducible growth environment with uniform TC-treated surfaces

Low contamination risk due to closed, sterile design

Straightforward scalability from T25 → T75 → T175 → T225

Cost-effective parallel experimentation

Improved morphological assessment compared with microplates

Cell culture flask thus act as the essential bridge between early clone screening and mid-scale process development.

6.Building a Robust Plate-to-Flask Workflow

A strong workflow typically includes:

1. Microplate screening → Identify top 5–20% candidate clones

2. Transfer to T25 cell culture flask → Confirm recovery and stability

3. Scale to T75/T175 → Assess productivity, metabolic behavior

4. Small-scale shake flask → Validate performance under dynamic conditions

5. Bioreactor entry → Only the most stable, consistent clones proceed

This ensures that only robust and scalable clones move forward in the pipeline.

7.Conclusion

The transition from plate to flask is a crucial step in CHO early development. While microplates enable high-throughput selection, cell culture flasks provide the controlled, biologically relevant environment necessary to confirm clone robustness, metabolic stability, and scalability.

By integrating flasks effectively into the CHO workflow, biopharmaceutical developers can accelerate process development, improve predictability, and significantly reduce downstream risks.