The importance of cell factory raw materials complying with the USP Class VI standard is self-evident. It ensures product quality and biocompatibility, providing a safe and reliable guarantee for the cell culture process.

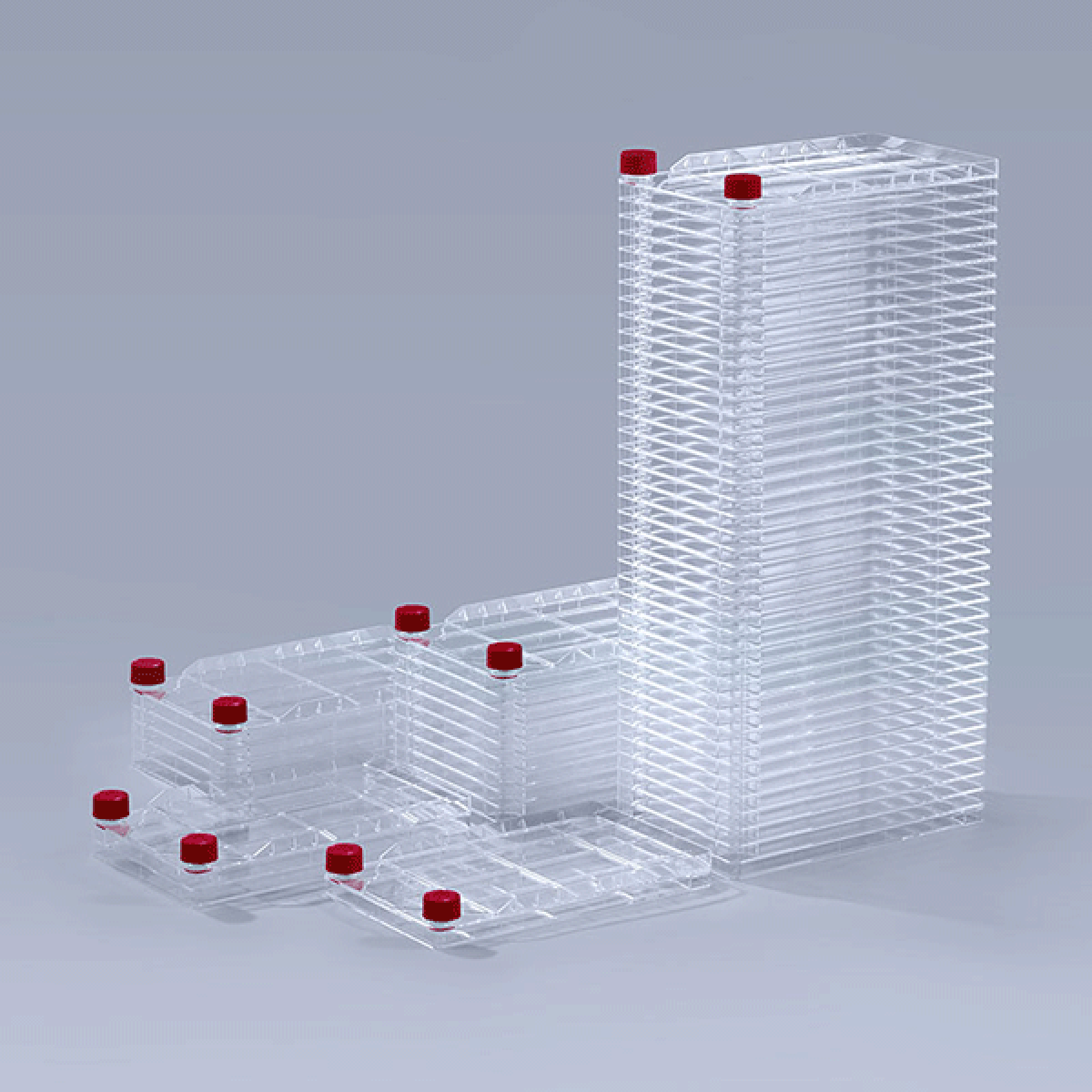

As a crucial tool for large-scale cell culture, the cell factory plays an indispensable role in the pharmaceutical field. However, the raw materials used in its manufacturing process are of paramount importance. The polystyrene used must comply with the USP Class VI standard to ensure product quality and safety. Do you know the reasons behind this?

Why do raw materials for cell factories need to comply with the USP Class VI standard?

Ensuring Product Quality: As key equipment used in biopharmaceutical and vaccine preparation, the quality of raw materials used in the manufacturing process of cell factories directly affects the quality of the final product. Using polystyrene that meets the USP Class VI standard can effectively prevent the leaching of harmful substances from the plastic material, ensuring stable cell growth during the cell culture process and the purity of the resulting products.

Ensuring Biocompatibility: The USP Class VI certification is a rigorous level of biocompatibility testing aimed at ensuring that medical devices or related products do not cause harmful reactions or long-term effects when in contact with human tissues. By complying with this standard, cell factory raw materials ensure that no chemicals harmful to cells or biological products are released during the cell culture process, thereby guaranteeing the safety of both the production process and the final product.

Content and Significance of the USP Class VI Standard:

Biocompatibility Testing: To obtain USP Class VI certification, a product must pass a series of complex biological tests. These involve preparing extracts of the product using different extraction media and injecting these extracts into test animals to observe the biological response. The tests are typically conducted according to the USP and include systemic injection, intracutaneous (intradermal), and implantation tests, among others.

Stringent Standard Requirements: The USP Class VI certification is the most stringent level among all USP tests. It requires that the product must not cause harmful reactions or long-term effects when in contact with human tissues. For example, in the implantation test, the plastic material must demonstrate low levels of toxicity and irritation to meet the USP Class VI requirements.

The importance of cell factory raw materials complying with the USP Class VI standard is self-evident. It ensures product quality and biocompatibility, providing a safe and reliable guarantee for the cell culture process. As the pharmaceutical field advances, the quality requirements for preparation tools and raw materials are becoming increasingly higher. Cell factory raw materials that meet the USP Class VI standard are a crucial assurance in meeting this demand.