As demand for monoclonal antibodies continues to rise, cell factory systems will remain a key technology for biopharmaceutical producers seeking robust and scalable upstream solutions.

Monoclonal antibodies (mAbs) have become one of the most important classes of biopharmaceutical products, widely used in oncology, immunology, infectious diseases, and autoimmune disorders. As global demand continues to grow, biomanufacturers must rely on highly efficient, scalable, and standardized upstream platforms for consistent antibody expression. While suspension cell culture remains the mainstream approach for many commercial processes, adherent cell lines and hybridoma-based platforms still depend heavily on systems that support surface-dependent cell growth.

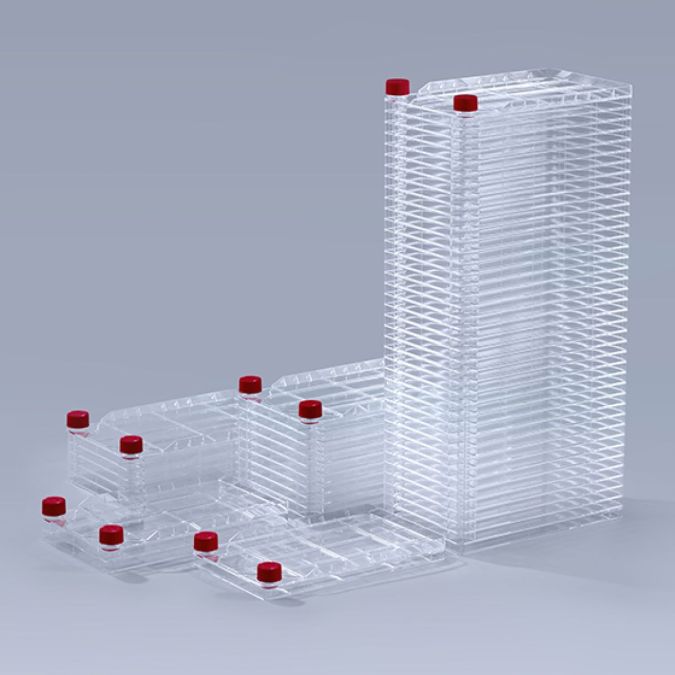

In this context, multilayer cell factory systems have emerged as an essential tool for scalable monoclonal antibody production, offering high-density adherent culture, reduced contamination risk, and strong alignment with GMP manufacturing workflows.

1. High-Density Culture for Enhanced Antibody Yield

Producing monoclonal antibodies from adherent hybridoma cells requires a large surface area to support cell attachment and optimal physiological performance. Cell factory systems provide:

Large total growth surface (e.g., up to 25,000 cm² in a 40-layer chamber)

Uniform TC-treated culture surfaces, promoting consistent cell adhesion

Optimized gas exchange across layers, supporting stable cell metabolism

Compared to roller bottles or traditional flasks, cell factories allow exponential scale-up without expanding the facility footprint, enabling manufacturers to achieve higher antibody yields with fewer units, shorter setup time, and more reproducible results.

2. Scalable and Modular Expansion from R&D to GMP Production

A key advantage of cell factory systems is their seamless scalability. The same culture principles apply across different formats—such as 1-layer, 5-layer, 10-layer, and 40-layer configurations—allowing easy technology transfer between development, pilot-scale, and full-scale manufacturing.

This modularity supports:

Fast scale-up without process redesign

Reduced qualification and validation time

Greater consistency across batches and sites

Because the core structure and process conditions remain the same, manufacturers can rapidly transition from laboratory optimization to commercial production while maintaining process continuity.

3. Closed System Operation Reduces Contamination Risk

Monoclonal antibody production requires strict aseptic control, especially for adherent cell lines that are sensitive to contamination. Modern cell factory systems support closed or semi-closed operation, using:

Sterile heat-sealed or silicone tubing assemblies

Pump-driven inoculation and harvesting

Filtered vent caps

Reduced manual handling

By minimizing open-air exposure, contamination risk is significantly reduced, and process reliability improves. Closed systems also help manufacturers meet international GMP requirements, improving traceability and compliance.

4. Improved Operational Efficiency and Lower Costs

Compared with multiple single-layer flasks or roller bottles, multilayer cell factories offer substantial resource savings:

Reduced labor due to fewer handling units

Lower incubator space requirements

Simplified media feeding and harvesting

Faster turnaround times in each production cycle

This makes cell factory systems ideal for facilities with limited space or those transitioning toward more standardized, automated workflows.

5. Compatibility with Process Automation and Upstream Integration

As biomanufacturers adopt automation to increase productivity and reduce human error, cell factory systems integrate smoothly into modern production lines through:

Automated filling and harvest systems

Peristaltic or pressure-driven pumps

Robotic handling equipment

Single-use tubing and connectors

These integrations enable fully controlled, repeatable operations, reducing variability and increasing overall process robustness.

6. Consistency and Standardization for Regulatory Compliance

Regulatory authorities require tight control over upstream monoclonal antibody production processes. Cell factory systems support compliance by offering:

Uniform manufacturing standards

Batch-to-batch reproducibility

Predictable surface chemistry and cell adhesion performance

High-quality, medical-grade raw materials

Traceable production workflows

This ensures consistent product quality during clinical and commercial manufacturing.

7. Ideal for Hybridoma-Based and Adherent Cell Line Applications

Although many antibody-producing cell lines have transitioned to suspension culture, cell factory systems remain invaluable for:

Classical hybridoma-based monoclonal antibody production

Cell lines that are difficult to adapt to suspension

Early-stage development and screening

Niche production where adherent morphology is required

Veterinary and diagnostic antibody manufacturing

Their flexibility allows them to meet the needs of both research and industrial-scale production.

Conclusion

Cell factory systems provide an efficient, scalable, and standardized platform for monoclonal antibody manufacturing, particularly when using adherent cell lines such as hybridomas. By offering high-density culture capacity, reduced contamination risk, modular scale-up pathways, and compatibility with closed and automated operations, they support reliable GMP-compliant production while minimizing costs and facility space.

As demand for monoclonal antibodies continues to rise, cell factory systems will remain a key technology for biopharmaceutical producers seeking robust and scalable upstream solutions.