In recent years, CAR-T cell therapy (Chimeric Antigen Receptor T-cell Therapy) has emerged as one of the most promising approaches in the field of cell and gene therapy. The manufacturing of CAR-T cells involves multiple steps—from T-cell isolation, activation, and transfection to large-scale expansion—each requiring tight control over the culture environment. During the early expansion and transf

In recent years, CAR-T cell therapy (Chimeric Antigen Receptor T-cell Therapy) has emerged as one of the most promising approaches in the field of cell and gene therapy. The manufacturing of CAR-T cells involves multiple steps—from T-cell isolation, activation, and transfection to large-scale expansion—each requiring tight control over the culture environment. During the early expansion and transfection stages, tissue culture flasks serve as a critical platform for maintaining cell viability, consistency, and genetic modification efficiency.

1. Stable Environment for Early T-Cell Expansion

At the initial stage of CAR-T preparation, the available T-cell population is limited. The culture system must ensure sufficient nutrient supply and gas exchange. Tissue culture flasks, made of polystyrene (PS) and treated for tissue culture provide an optimized surface that supports cell activation and adhesion. This surface property enhances nutrient uptake and metabolic stability, facilitating higher initial proliferation rates of T cells.

2. Optimized Conditions for Transfection

The introduction of CAR genes—via viral vectors such as lentivirus or retrovirus, or through non-viral systems—requires a stable and low-shear culture environment. Tissue culture flasks provide such conditions, allowing efficient interaction between viral particles and T cells while minimizing mechanical stress. Their optical clarity also enables real-time microscopic observation of transfection efficiency and cell morphology, ensuring successful gene delivery.

3. Ensuring Reproducibility and Traceability

Consistency is essential in CAR-T production. Tissue culture flasks are standardized and traceable, reducing batch-to-batch variability caused by vessel differences. This feature is particularly valuable during early process development and preclinical manufacturing, where reproducibility directly affects scale-up reliability.

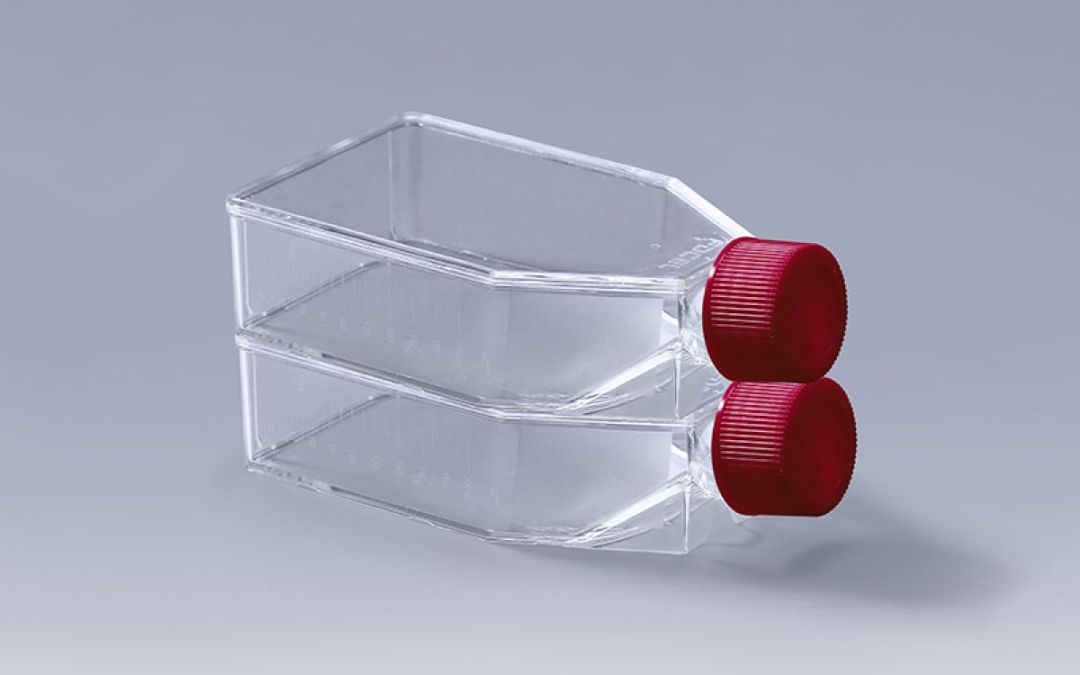

4. Transitioning to Large-Scale Culture

As cell numbers increase, the culture process gradually shifts from tissue culture flasks to multilayer cell factories or bioreactors. Data obtained from early flask-based studies provide essential parameters for scale-up, such as media composition, gas exchange rate, and optimal cell density. This knowledge ensures smoother transitions and consistent outcomes during large-scale expansion.

In summary, tissue culture flasks are not merely tools for initial cell culture—they are the foundation of reproducible CAR-T cell development, providing a controlled environment that supports both early-stage research and scalable manufacturing in the evolving field of cell therapy.