As gene therapy continues to expand from clinical trials to commercial-scale manufacturing, cell factory systems will remain an essential component of efficient, safe, and standardized viral vector production.

Gene therapy has emerged as a transformative approach for treating genetic disorders, cancers, and rare diseases. At the core of gene therapy manufacturing lies the reliable production of viral vectors such as AAV, lentivirus, and adenovirus. These vectors require robust upstream cell culture platforms that ensure high yield, consistency, and strict aseptic control.

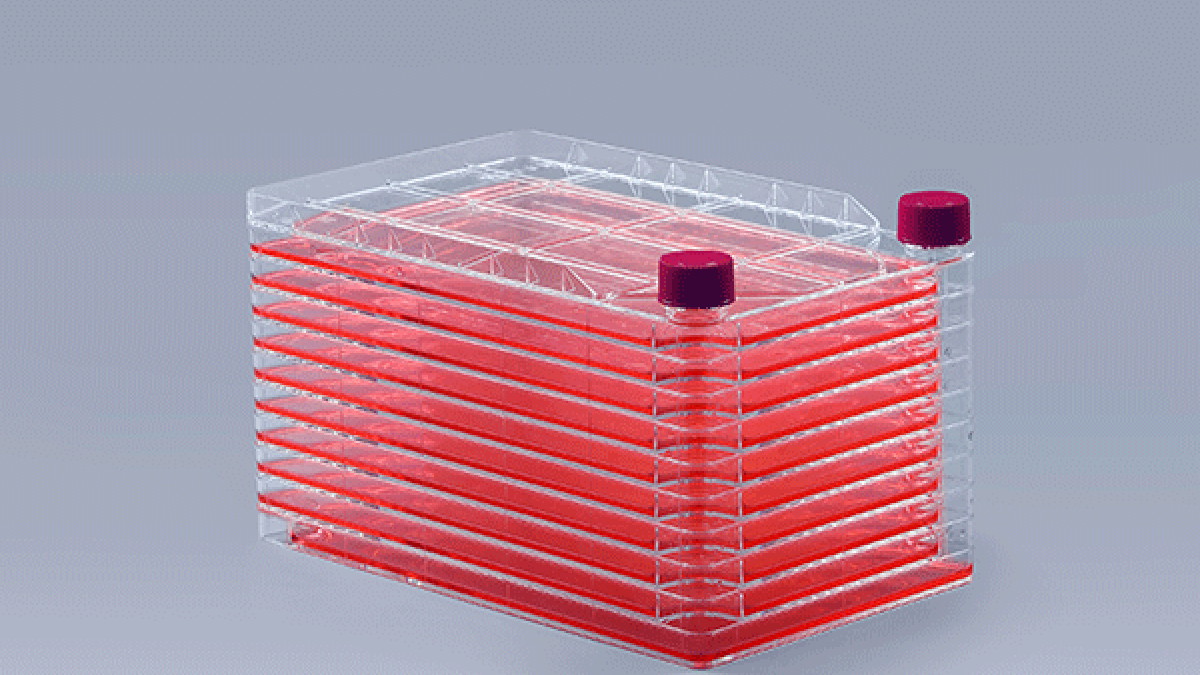

In this context, the Cell Factory, particularly the Multilayer Cell Factory (cell stack), plays a critical role in scalable and standardized viral vector production.

1. Cell Factories as a Foundation for Adherent Viral Vector Production

Most viral vectors used in gene therapy are produced using adherent cell lines, including HEK293, HEK293T, and Vero cells. These cells require large, uniform growth surfaces to support efficient transfection and virus assembly.

Multilayer Cell Factory provide:

Large surface areas for high-density adherent culture

Uniform TC-treated surfaces for consistent cell attachment

Optimized gas exchange across stacked layers

Compared to traditional flasks or roller bottles, a single cell stack can replace dozens of individual vessels while maintaining consistent culture conditions, making it ideal for viral vector manufacturing.

2. Scalability and Process Standardization

One of the greatest advantages of Multilayer Cell Factory is their linear scalability. Cell stacks are available in multiple formats, ranging from a few layers to high-layer configurations, allowing seamless scale-up from process development to GMP manufacturing without altering core culture parameters.

This scalability supports:

Predictable vector yields during scale-up

Simplified process validation

Reduced batch-to-batch variability

Standardized geometry and surface chemistry enable reproducible transfection efficiency and viral harvest performance across production runs.

3. Closed and Semi-Closed Operation for Enhanced Biosafety

Viral vector production requires high biosafety standards due to the use of replication-deficient viruses and genetically modified cells. Cell factories support closed or semi-closed systems through:

Sterile tubing assemblies

Pump-driven media exchange and harvest

Filtered vent caps for controlled gas exchange

These features minimize open handling, significantly reducing contamination risk and enhancing operator safety, especially in GMP and cleanroom environments.

4. Compatibility with Transfection and Harvest Workflows

Efficient gene therapy vector production depends on precise control of transfection timing, media exchange, and virus collection. Multilayer Cell Factory are well suited for:

Chemical and plasmid-based transfection protocols

High-volume media exchange with minimal shear stress

Multiple harvest cycles for lentiviral and AAV production

The integrated design of cell stacks ensures uniform exposure to transfection reagents, supporting consistent vector potency and yield.

5. Operational Efficiency and Facility Optimization

By consolidating large culture surfaces into a compact footprint, cell factory significantly improve operational efficiency:

Reduced incubator and cleanroom space requirements

Fewer handling steps compared to multiple flasks

Lower labor costs and reduced human error

These benefits are particularly valuable for gene therapy facilities facing space constraints and rapid production timelines.

6. Integration with Automation and Single-Use Technologies

Modern gene therapy manufacturing increasingly relies on automation and single-use solutions. Cell factory integrate easily with:

Peristaltic pumps and automated filling systems

Single-use tubing and connectors

Robotic handling and closed fluid transfer

This integration supports standardized, reproducible workflows while maintaining flexibility across different viral vector platforms.

---

7. Enabling Consistency and Regulatory Compliance

Regulatory authorities require robust control over viral vector manufacturing processes. Multilayer Cell Factory support compliance by providing:

Consistent culture performance

Traceable and standardized consumables

Compatibility with GMP documentation and validation

Reduced risk of cross-contamination

These attributes make cell factories a trusted platform for both clinical and commercial gene therapy vector production.

Conclusion

Cell Factory, particularly Multilayer Cell Factory, play a critical role in gene therapy vector production. By enabling high-density adherent cell culture, scalable manufacturing, closed-system operation, and compatibility with automated workflows, they address the key challenges of viral vector production.

As gene therapy continues to expand from clinical trials to commercial-scale manufacturing, cell factory systems will remain an essential component of efficient, safe, and standardized viral vector production.