HEK293 viral vector production is highly sensitive to upstream variables, and Cell Culture Flask quality is one of the most underappreciated factors. Surface uniformity, sterility, and manufacturing consistency all play critical roles in determining transfection efficiency, viral yield, and reproducibility.

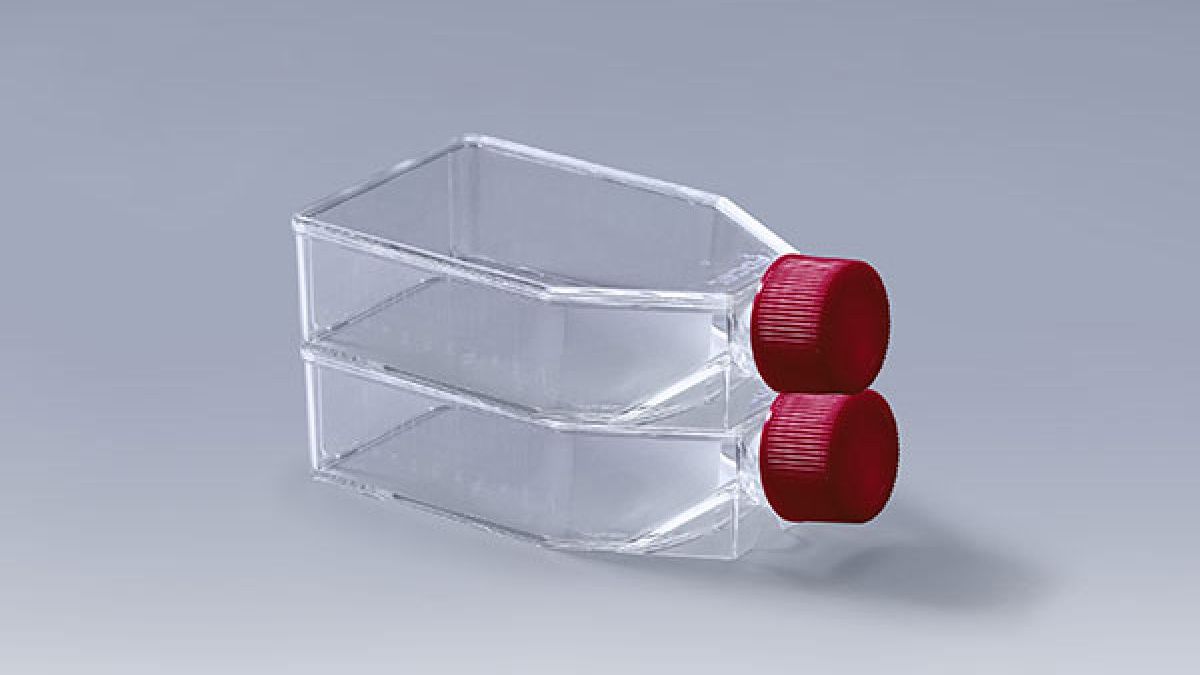

HEK293 cells are a cornerstone of viral vector manufacturing, widely used for the production of lentivirus, AAV, and adenoviral vectors. While much attention is paid to plasmid design, transfection reagents, and upstream protocols, one critical factor often receives less scrutiny: the quality of the Cell Culture Flask used for HEK293 expansion and production.

In viral vector workflows, small variations at the flask level can translate into significant differences in viral yield, consistency, and process robustness.

HEK293 Viral Vector Production Depends on Stable Adherent Growth

Most HEK293-based viral vector processes rely on adherent cultures, especially during early-stage development and pilot-scale production. In these systems, cell attachment quality directly influences transfection efficiency and vector assembly.

A high-quality Cell Culture Flask provides:

Uniform surface treatment for consistent cell attachment

Stable cell morphology across the growth area

Predictable confluence at the time of transfection

When Cell Flask quality is inconsistent, HEK293 cells may show uneven growth patterns, leading to localized differences in transfection and viral particle formation.

Surface Uniformity Drives Transfection and Vector Yield

Viral vector production in HEK293 cells is highly sensitive to transfection conditions. Non-uniform surfaces within a Cell Culture Flask can result in:

Patchy cell layers with variable density

Uneven plasmid uptake across the culture

Inconsistent expression of viral components

These effects often manifest as fluctuating viral titers between runs, even when the same transfection protocol is used.

Uniform surface treatment in a Cell Flask helps ensure that HEK293 cells respond consistently to transfection reagents, supporting stable and reproducible vector yields.

Flask-to-Flask Consistency Matters More Than Expected

In viral vector workflows, reproducibility is critical—not only within a single experiment, but across batches and production cycles. Variability between Cell Culture Flasks can introduce hidden process instability, including:

Increased run-to-run variability

Additional process troubleshooting

Challenges during scale-up or tech transfer

High-quality Cell Flask with tight manufacturing and QC controls reduce these risks by providing consistent growth conditions from one flask to the next.

Sterility and Contamination Risk in Viral Vector Production

HEK293 viral vector processes are particularly sensitive to contamination. Even low-level microbial contamination can compromise:

Cell viability and productivity

Vector integrity and safety

Regulatory confidence in the process

A reliable Cell Culture Flask must meet stringent sterility standards to protect both cells and viral products. Inconsistent sealing, packaging, or sterilization can expose viral vector workflows to unnecessary risk.

Why Cell Flask Quality Becomes a Bottleneck at Scale

As HEK293 viral vector production moves from research to process development, the limitations of low-quality Cell Culture Flasks become more apparent. Issues that may be manageable at small scale can quickly become bottlenecks when:

Multiple flasks are used in parallel

Production timelines tighten

Consistency becomes a regulatory expectation

At this stage, Cell Flasks are no longer simple consumables—they become critical process inputs that influence yield, cost, and scalability.

Choosing Cell Culture Flask for HEK293 Viral Vector Workflows

For teams working with HEK293-based viral vector production, selecting the right Cell Flask involves more than choosing a size. Key considerations include:

Uniform and reproducible surface treatment

Reliable sterility assurance

Batch-to-batch consistency

Compatibility with transfection and viral production workflows

Investing in high-quality Cell Culture Flasks can significantly reduce variability and support more predictable viral vector manufacturing outcomes.

Conclusion

HEK293 viral vector production is highly sensitive to upstream variables, and Cell Culture Flask quality is one of the most underappreciated factors. Surface uniformity, sterility, and manufacturing consistency all play critical roles in determining transfection efficiency, viral yield, and reproducibility.

By prioritizing reliable Cell Flask, researchers and bioprocess teams can build more stable HEK293 viral vector workflows and reduce avoidable process risk.